Metal Roofing Installation Prep

If you’re looking to replace your current roof, metal roofing is a durable, low-maintenance alternative to asphalt shingles. To make the most of your investment, it’s important to plan ahead for the metal roof installation process. Learn about the steps that you and your contractor should take to prepare for metal roofing installation.

Consider Metal Roofing Options: Profiles, Gauge, Color, Etc.

Consult with a local distributor to select metal roofing materials for your building project. They’ll be able to provide resources such as product information, color charts, technical literature and product samples.

There are several factors to consider when selecting metal roofing panels. The most important consideration is the roof pitch. Make sure to choose a metal panel profile that will perform best with the pitch of your roof in order to keep it weathertight. Once you’ve selected the panel style, choose from a variety of profiles and colors depending on your budget and aesthetic preferences.

For residential applications, the MasterRib® panel, an exposed fastener panel, offers rustic charm. The SL-16® panel, a concealed fastener panel, provides a clean, sleek aesthetic.

Choose a Contractor

Next, you’ll need to select a contractor. During this process, it’s important to choose a contractor that has experience installing metal roofing. In many cases, your local distributor can provide references to narrow down your search.

Building Owner Prep Work

Although the contractor will be responsible for most of the heavy lifting, there are a few things you should do to prepare for metal roof panel installation.

Clear the Space

Make sure to clear the space around your home or building to prepare an adequate workspace for your contractor. For commercial properties, you may want to set up barriers to keep your customers safe. For residential buildings, you should remove items from the yard, patio, deck or balcony to keep them from being damaged. Consider protecting landscaping that’s in close proximity to the building by covering it with a tarp.

Alert Your Neighbors

As a courtesy to your neighbors, consider warning them about the loud noises that will likely occur during the metal roofing installation process.

Make Arrangements

Make arrangements for any individuals that may be disturbed by the noise. For residential buildings, you should also make arrangements for pets that may need to go outside during the day.

Contractor Prep Work

Measure the Roof & Create a Materials List

Once you’ve hired a contractor, they’ll begin their prep work by measuring the roof to create a materials list and determine order quantities. This list should contain all of the necessary materials including:

- Panels

- Trim (Edging)

- Screws

- Closure Strips/Closures

- Venting Material

- Other Roofing Accessories

Before the materials list is finalized, you should discuss with your contractor whether or not to vent the ridge cap. In residential situations, this is necessary to circulate air throughout the house.

Order Materials

In most cases, your contractor will be responsible for ordering the roofing materials through the local distributor. Before the order is placed, consider which warranty option is best for you. While a 40-year warranty is the most common choice, some of the lighter gauge materials offer a 20-year warranty option.

Inspect Material

Once the roofing materials are delivered, it’s important to inspect them. Your contractor should do the following:

- Check the bill of lading to make sure that all materials have been delivered

- Check the materials for damage including dents and scratched paint

- If something is wrong with the order, contact the distributor to order replacement materials

Remove Old Roofing and Repair Damage

Remove the existing roofing down to the decking. After the existing roofing materials have been removed, the installer should check for bad decking and make any necessary repairs. All ice and water shields and underlayment should be removed and replaced as well.

Metal Roofing Installation

After all of the prep work is completed, the metal roof installation process can begin. During the installation process, it’s important to communicate with the main contact for your project about any concerns you may have. Once the installation process has been completed, make sure the work is done to your liking. Be sure to finalize payment and warranty information as well.

To learn more about the best practices for metal roof installation, contact your local ABC representative.

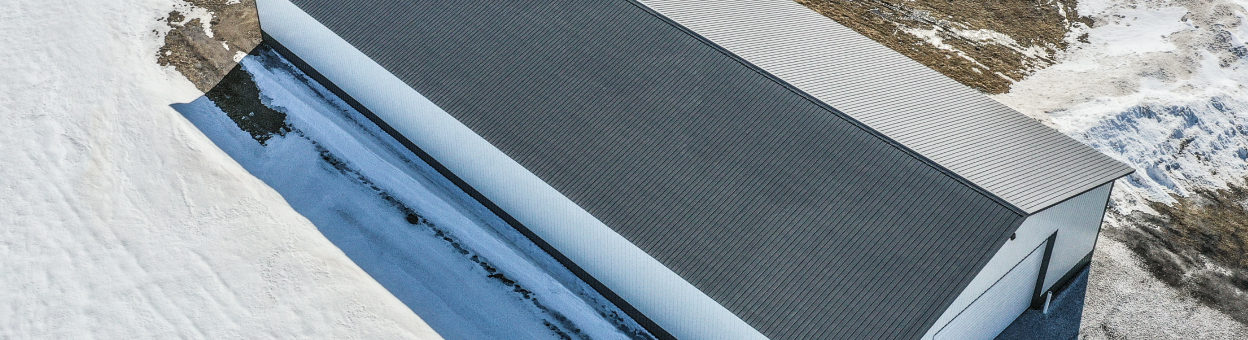

A versatile and practical choice, IMPs are designed for many roof and vertical and horizontal wall applications—including ceiling panels and wall partitions for commercial, industrial and post-frame building types. IMPs are ideal for sustainability-minded designs, offering excellent R-values (indicating their insulating power) and improving energy efficiency. What’s more, they’re available in various colors, thicknesses, widths and finishes, providing many customization options to choose from.

A versatile and practical choice, IMPs are designed for many roof and vertical and horizontal wall applications—including ceiling panels and wall partitions for commercial, industrial and post-frame building types. IMPs are ideal for sustainability-minded designs, offering excellent R-values (indicating their insulating power) and improving energy efficiency. What’s more, they’re available in various colors, thicknesses, widths and finishes, providing many customization options to choose from.