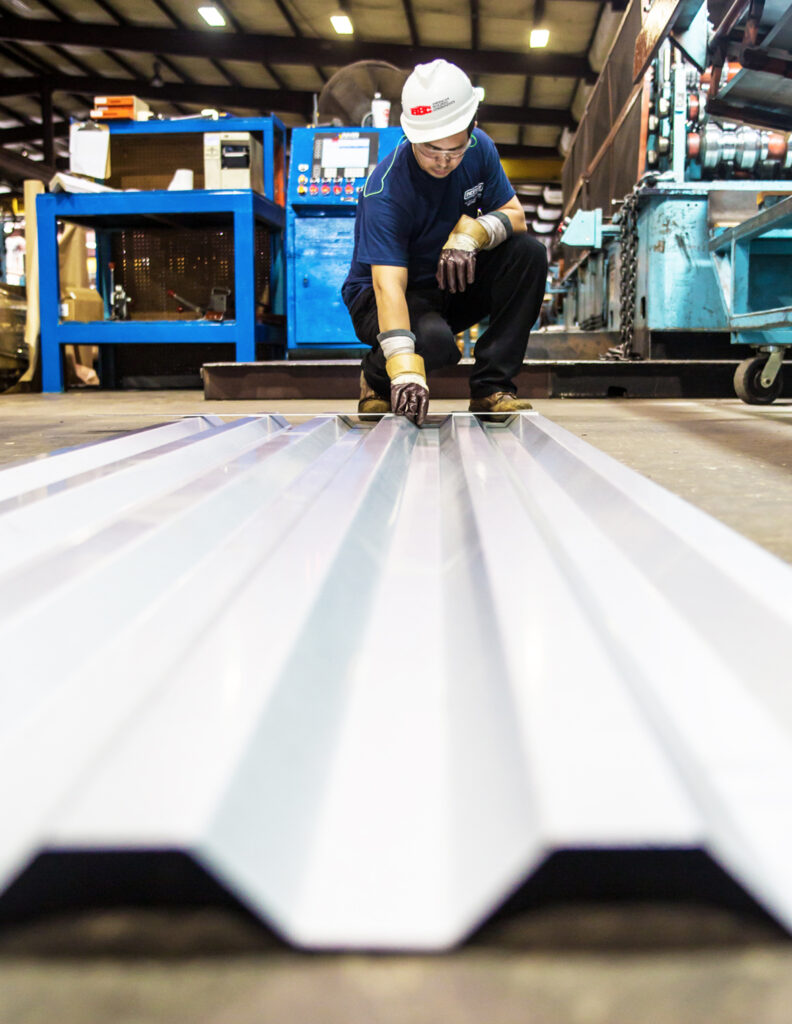

All metal panels—whether for commercial, residential, industrial or agricultural applications—are attached to the structure using either fasteners, clips or a combination of both that keep them in place. Vertical panels, in particular, are often categorized by the type of fastening method used to attach them, which is most often either using hidden/concealed fasteners or using an exposed (through-fastened) method. Here we’ll look at the benefits your customers can experience when using these common fastening types, as well as their differentiators, including price/budget, durability, aesthetics and ease of installation.

Concealed-Fastened Roofing Panels

Concealed-fastened panels are attached to the substrate with clips, which means the panels are not pierced to secure the connection. The clips and fasteners, therefore, are concealed underneath the metal panels when properly installed—arguably making the roof more aesthetically pleasing. These panels are offered in various styles, depending on which options your customers choose and additional job-specific considerations. This method is common in architectural and residential applications where a clean appearance and protection from environmental exposure are priorities.

Through-Fastened (Exposed) Roofing Panels

Through-fastened panels are generally attached with screws or nails, which puncture the overlapping roofing sections to lock the panels into place. They are also installed using washers, which provide leakage protection around the puncture hole. The fasteners are on the outside face of the panel and are visible even after the installation is complete.

So, how do your customers decide which option is right for their project? See below for some factors that can help them choose between a concealed- or through-fastened approach.

Key Considerations

Price/Budget:

Concealed: Typically, concealed-fastened panels can be more expensive overall due to the longer installation time required. In addition to increasing the labor cost, this installation method also takes longer, which affects your customer’s project schedule. However, ABC’s SL-16® panel can be installed faster and for about the same cost as exposed-fastened panel systems.

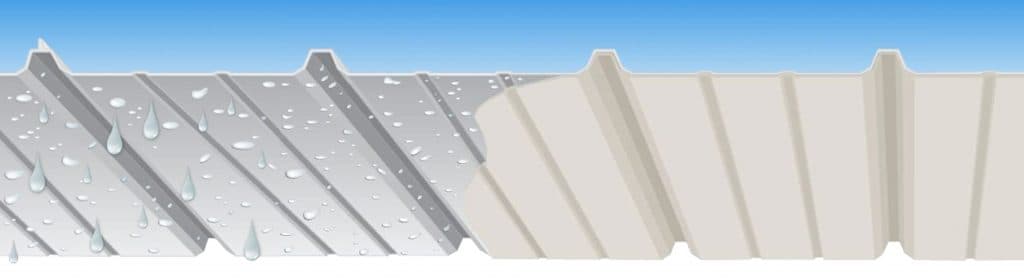

Through-fastened: While less expensive, through-fastened applications are more prone to issues. For example, if a washer fails, the screw can pop, which allows water in and can cause leaks and corrosion. While washer material is of a higher quality and more dependable than in the past, this is still a concern.

Durability:

Concealed: Because concealed fasteners have limited weather exposure, they therefore generally have a longer lifespan than panels with exposed fasteners. Additionally, there is less wear and tear since concealed panel fasteners are not as affected by the metal panel expansion and contraction that occurs when temperatures fluctuate as exposed-fastened panels are.

Through-fastened: Because concealed fasteners have limited weather exposure, they generally have a longer lifespan than panels with exposed fasteners. Additionally, there is less wear and tear since concealed panel fasteners are not as affected by the metal panel expansion and contraction that occurs when temperatures fluctuate as exposed-fastened panels are.

Aesthetics:

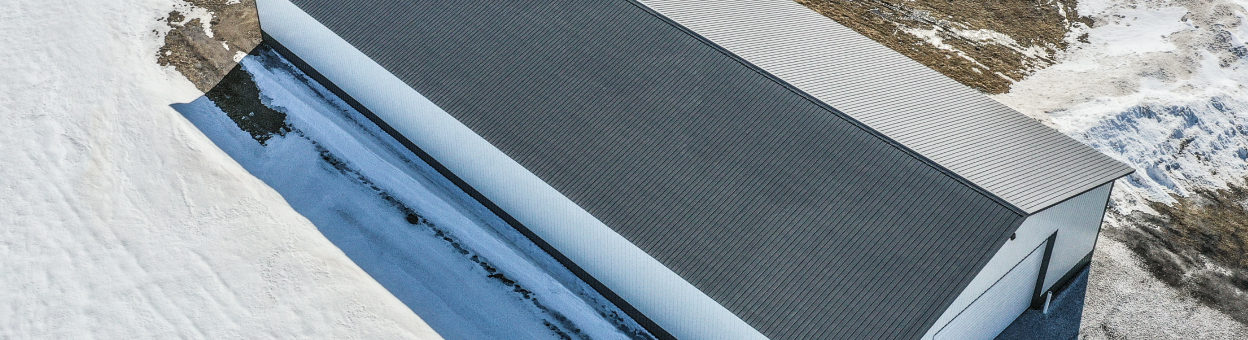

Concealed: Aesthetically, the main question is whether your customers want the screws to be visible or if it’s important that they are hidden. A concealed-fastened application is considered more aesthetically pleasing, as the lack of visible fasteners, creating a smooth, clean appearance. Generally, residential and architectural buildings favor concealed-fastened roofing panels.

Through-fastened: As stated, the hundreds of fasteners required to secure panels are exposed and visible on the outside of the panels. This method is often used on agricultural and industrial buildings, as clean aesthetics are usually less important for customers in these markets.

Ease of Installation:

Concealed: Installing concealed-fastened metal panel systems is time-consuming and complicated as compared to through-fastened. In fact, the complexity of the process dissuades many DIY installers from taking on the task.

Through-fastened: Exposed-fastened metal panel systems require less installation time as each fastener is drilled directly onto the outside of the panels. This makes it the method of choice for the majority of DIY installers. Overall, this method works well with simple structures but can be difficult to use on more complex projects. It should also be noted that through-fastened panels should be installed with care so that there is proper sealing. There also may be length limitations due to thermal movement.

Conclusion

The type of fastener system your customers choose for a given metal panel project will depend on a wide array of factors—budget, durability, aesthetics and ease of installation. Making the right choice is one step in ensuring the success and integrity of their building for years to come.

For more information on ABC’s concealed and through-fastened metal panels, visit our website. As always, our team is ready to help with your metal panel needs, so reach out to your local representative today!

What causes condensation on metal panels?

What causes condensation on metal panels?